big largest touch screen is golliwog or it is something belong to reality

big or larger screen. is possible but......... touch screen it is real or stupid thinking .

now we talk about some real concept and all about touch screen

A touchscreen is an input and output device normally layered on the top of an electronic visual display of an information processing system. A user can give input or control the information processing system through simple or multi-touch gestures by touching the screen with a special stylus and/or one or more fingers.[1] Some touchscreens use ordinary or specially coated gloves to work while others may only work using a special stylus/pen. The user can use the touchscreen to react to what is displayed and to control how it is displayed; for example, zooming to increase the text size.

The touchscreen enables the user to interact directly with what is displayed, rather than using a mouse, touchpad, or any other such device (other than a stylus, which is optional for most modern touchscreens).

Touchscreens are common in devices such as game consoles, personal computers, tablet computers, electronic voting machines, point of sale systems, and smartphones. They can also be attached to computers or, as terminals, to networks. They also play a prominent role in the design of digital appliances such as personal digital assistants (PDAs) and some e-readers.

The popularity of smartphones, tablets, and many types of information appliances is driving the demand and acceptance of common touchscreens for portable and functional electronics. Touchscreens are found in the medical field and in heavy industry, as well as for automated teller machines (ATMs), and kiosks such as museum displays or room automation, where keyboard and mouse systems do not allow a suitably intuitive, rapid, or accurate interaction by the user with the display's content.

Historically, the touchscreen sensor and its accompanying controller-based firmware have been made available by a wide array of after-market system integrators, and not by display, chip, or motherboard manufacturers. Display manufacturers and chip manufacturers worldwide have acknowledged the trend toward acceptance of touchscreens as a highly desirable user interface component and have begun to integrate touchscreens into the fundamental design of their products.

Technologies

There are a variety of touchscreen technologies with different methods of sensing touch.[26]

Resistive[edit]

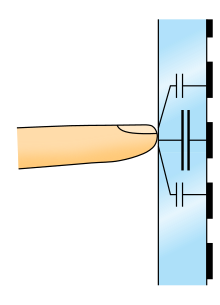

A resistive touchscreen panel comprises several layers, the most important of which are two thin, transparent electrically resistive layers separated by a thin space. These layers face each other with a thin gap between. The top screen (the screen that is touched) has a coating on the underside surface of the screen. Just beneath it is a similar resistive layer on top of its substrate. One layer has conductive connections along its sides, the other along top and bottom. A voltage is applied to one layer, and sensed by the other. When an object, such as a fingertip or stylus tip, presses down onto the outer surface, the two layers touch to become connected at that point: The panel then behaves as a pair of voltage dividers, one axis at a time. By rapidly switching between each layer, the position of a pressure on the screen can be read.

Resistive touch is used in restaurants, factories and hospitals due to its high resistance to liquids and contaminants. A major benefit of resistive touch technology is its low cost. Additionally, as only sufficient pressure is necessary for the touch to be sensed, they may be used with gloves on, or by using anything rigid as a finger/stylus substitute. Disadvantages include the need to press down, and a risk of damage by sharp objects. Resistive touchscreens also suffer from poorer contrast, due to having additional reflections from the extra layers of material (separated by an air gap) placed over the screen.[31] This is the type of touchscreen used by Nintendo in the DS family, the 3DS family, and the Wii U GamePad.[32]

Surface acoustic wave[edit]

Surface acoustic wave (SAW) technology uses ultrasonic waves that pass over the touchscreen panel. When the panel is touched, a portion of the wave is absorbed. This change in the ultrasonic waves registers the position of the touch event and sends this information to the controller for processing. Surface acoustic wave touchscreen panels can be damaged by outside elements. Contaminants on the surface can also interfere with the functionality of the touchscreen.[33]

Capacitive[edit]

A capacitive touchscreen panel consists of an insulator such as glass, coat with a transparent conductor such as indium tin oxide (ITO).[34]As the human body is also an electrical conductor, touching the surface of the screen results in a distortion of the screen's electrostatic field, measurable as a change in capacitance. Different technologies may be used to determine the location of the touch. The location is then sent to the controller for processing.

Unlike a resistive touchscreen, one cannot use a capacitive touchscreen through most types of electrically insulating material, such as gloves. This disadvantage especially affects usability in consumer electronics, such as touch tablet PCs and capacitive smartphones in cold weather. It can be overcome with a special capacitive stylus, or a special-application glove with an embroidered patch of conductive thread passing through it and contacting the user's fingertip.

The largest capacitive display manufacturers continue to develop thinner and more accurate touchscreens, with touchscreens for mobile devices now being produced with 'in-cell' technology that eliminates a layer, such as Samsung's Super AMOLED screens, by building the capacitors inside the display itself. This type of touchscreen reduces the visible distance (within millimetres) between the user's finger and what the user is touching on the screen, creating a more direct contact with the content displayed and enabling taps and gestures to be more responsive.

A simple parallel plate capacitor has two conductors separated by a dielectric layer. Most of the energy in this system is concentrated directly between the plates. Some of the energy spills over into the area outside the plates, and the electric field lines associated with this effect are called fringing fields. Part of the challenge of making a practical capacitive sensor is to design a set of printed circuit traces which direct fringing fields into an active sensing area accessible to a user. A parallel plate capacitor is not a good choice for such a sensor pattern. Placing a finger near fringing electric fields adds conductive surface area to the capacitive system. The additional charge storage capacity added by the finger is known as finger capacitance, CF. The capacitance of the sensor without a finger present is denoted as CP in this article, which stands for parasitic capacitance.

Surface capacitance[edit]

In this basic technology, only one side of the insulator is coated with a conductive layer. A small voltage is applied to the layer, resulting in a uniform electrostatic field. When a conductor, such as a human finger, touches the uncoated surface, a capacitor is dynamically formed. The sensor's controller can determine the location of the touch indirectly from the change in the capacitance as measured from the four corners of the panel. As it has no moving parts, it is moderately durable but has limited resolution, is prone to false signals from parasitic capacitive coupling, and needs calibration during manufacture. It is therefore most often used in simple applications such as industrial controls and kiosks.[35]

Projected capacitance[edit]

Projected capacitive touch (PCT; also PCAP) technology is a variant of capacitive touch technology. All PCT touch screens are made up of a matrix of rows and columns of conductive material, layered on sheets of glass. This can be done either by etching a single conductive layer to form a grid pattern of electrodes, or by etching two separate, perpendicular layers of conductive material with parallel lines or tracks to form a grid. Voltage applied to this grid creates a uniform electrostatic field, which can be measured. When a conductive object, such as a finger, comes into contact with a PCT panel, it distorts the local electrostatic field at that point. This is measurable as a change in capacitance. If a finger bridges the gap between two of the "tracks", the charge field is further interrupted and detected by the controller. The capacitance can be changed and measured at every individual point on the grid (intersection). Therefore, this system is able to accurately track touches.[36] Due to the top layer of a PCT being glass, it is a more robust solution than less costly resistive touch technology. Additionally, unlike traditional capacitive touch technology, it is possible for a PCT system to sense a passive stylus or gloved fingers. However, moisture on the surface of the panel, high humidity, or collected dust can interfere with the performance of a PCT system. There are two types of PCT: mutual capacitance and self-capacitance.

Mutual capacitance[edit]

This is a common PCT approach, which makes use of the fact that most conductive objects are able to hold a charge if they are very close together. In mutual capacitive sensors, a capacitor is inherently formed by the row trace and column trace at each intersection of the grid. A 16-by-14 array, for example, would have 224 independent capacitors. A voltage is applied to the rows or columns. Bringing a finger or conductive stylus close to the surface of the sensor changes the local electrostatic field which reduces the mutual capacitance. The capacitance change at every individual point on the grid can be measured to accurately determine the touch location by measuring the voltage in the other axis. Mutual capacitance allows multi-touch operation where multiple fingers, palms or styli can be accurately tracked at the same time.

Self-capacitance[edit]

Self-capacitance sensors can have the same X-Y grid as mutual capacitance sensors, but the columns and rows operate independently. With self-capacitance, the capacitive load of a finger is measured on each column or row electrode by a current meter. This method produces a stronger signal than mutual capacitance, but it is unable to resolve accurately more than one finger, which results in "ghosting", or misplaced location sensing.

Use of styli on capacitive screens[edit]

Capacitive touchscreens do not necessarily need to be operated by a finger, but until recently the special styli required could be quite expensive to purchase. The cost of this technology has fallen greatly in recent years and capacitative styli are now widely available for a nominal charge, and often given away free with mobile accessories.

Infrared grid[edit]

An infrared touchscreen uses an array of X-Y infrared LED and photodetector pairs around the edges of the screen to detect a disruption in the pattern of LED beams. These LED beams cross each other in vertical and horizontal patterns. This helps the sensors pick up the exact location of the touch. A major benefit of such a system is that it can detect essentially any input including a finger, gloved finger, stylus or pen. It is generally used in outdoor applications and point of sale systems which can not rely on a conductor (such as a bare finger) to activate the touchscreen. Unlike capacitive touchscreens, infrared touchscreens do not require any patterning on the glass which increases durability and optical clarity of the overall system. Infrared touchscreens are sensitive to dirt/dust that can interfere with the IR beams, and suffer from parallax in curved surfaces and accidental press when the user hovers his/her finger over the screen while searching for the item to be selected.

Infrared acrylic projection[edit]

A translucent acrylic sheet is used as a rear projection screen to display information. The edges of the acrylic sheet are illuminated by infrared LEDs, and infrared cameras are focused on the back of the sheet. Objects placed on the sheet are detectable by the cameras. When the sheet is touched by the user the deformation results in leakage of infrared light, which peaks at the points of maximum pressure indicating the user's touch location. Microsoft's PixelSense tables use this technology.

Optical imaging[edit]

Optical touchscreens are a relatively modern development in touchscreen technology, in which two or more image sensors are placed around the edges (mostly the corners) of the screen. Infrared back lights are placed in the camera's field of view on the other side of the screen. A touch shows up as a shadow and each pair of cameras can then be pinpointed to locate the touch or even measure the size of the touching object (see visual hull). This technology is growing in popularity, due to its scalability, versatility, and affordability, especially for bigger units.

Dispersive signal technology[edit]

Introduced in 2002, by 3M, this system uses sensors to detect the piezoelectricity in the glass that occurs due to a touch. Complex algorithms then interpret this information and provide the actual location of the touch.[37] The technology claims to be unaffected by dust and other outside elements, including scratches. Since there is no need for additional elements on screen, it also claims to provide excellent optical clarity. Also, since mechanical vibrations are used to detect a touch event, any object can be used to generate these events, including fingers and stylus. A downside is that after the initial touch the system cannot detect a motionless finger.

Acoustic pulse recognition[edit]

The key to this technology is that a touch at any one position on the surface generates a sound wave in the substrate which then produces a unique combined sound after being picked up by three or more tiny transducers attached to the edges of the touchscreen. The sound is then digitized by the controller and compared to a list of pre-recorded sounds for every position on the surface. The cursor position is instantly updated to the touch location. A moving touch is tracked by rapid repetition of this process. Extraneous and ambient sounds are ignored since they do not match any stored sound profile. The technology differs from other attempts to recognize the position of touch with transducers or microphones in using a simple table look-up method, rather than requiring powerful and expensive signal processing hardware to attempt to calculate the touch location without any references. As with the dispersive signal technology system, a motionless finger cannot be detected after the initial touch. However, for the same reason, the touch recognition is not disrupted by any resting objects. The technology was created by SoundTouch Ltd in the early 2000s, as described by the patent family EP1852772, and introduced to the market by Tyco International's Elo division in 2006 as Acoustic Pulse Recognition.[38] The touchscreen used by Elo is made of ordinary glass, giving good durability and optical clarity. APR is usually able to function with scratches and dust on the screen with good accuracy. The technology is also well suited to displays that are physically larger.

NOW point of the article is what is the purpose to get the largest touch screen why not in economical

we already deals with largest no of displays like gorilla 1 2 3 and many more so what is the difference

the difference is very simple and complicated is the work load of 50000 pound is done by either ant or elephant then the answer is elephant and it is how you already read the question thats the reason we are able to make best pixel per inch displays we can make also better bigger but the problems is developed in front of making of bigger lager displays is are

- expensiveness

- heating problems due to bigger displays it can destroy it too

- calibration problem

- due to larger touch screen it needs much power so it cannot be hold or stands with +5volts

Comments

Post a Comment